ZV-1F – capturing our environmental vision

Aiming to achieve a zero environmental footprint

Inspired by the beauty of the world, Sony is paying attention to the need to help preserve the Earth, while still allowing creators to produce even more beautiful and creative imagery.

With goals of achieving net-zero emissions across the entire Sony Group by 2040 and a zero environmental footprint by the year 2050, we are accelerating numerous initiatives.

With goals of achieving net-zero emissions across the entire Sony Group by 2040 and a zero environmental footprint by the year 2050, we are accelerating numerous initiatives.

Products for people and the environment

Newly-developed wind screen using recycled PET bottles0

At Sony, we’ve extended the use of recycled materials beyond the camera body to a wind screen. Developed through careful testing of sound quality performance and wind protection efficacy, it’s made exclusively from recycled PET bottles0, lessening our environmental impact while maintaining performance.

Designing a better future with SORPLAS™

SORPLAS is made from used water bottles and waste optical discs collected from factories and markets, and a proprietary flame retardant. It’s used in a variety of Sony and external products. SORPLAS won’t degrade too much even after being recycled several times, so in the future, we are hopeful that SORPLAS will be recovered and reused in new products.

High recycled content, up to 99%

Recycled plastic used in electronics is typically only around 30%0 recycled content. Our groundbreaking sulfur-based flame retardant produces consistently high-performance plastic even when using up to 99%2 recycled content.

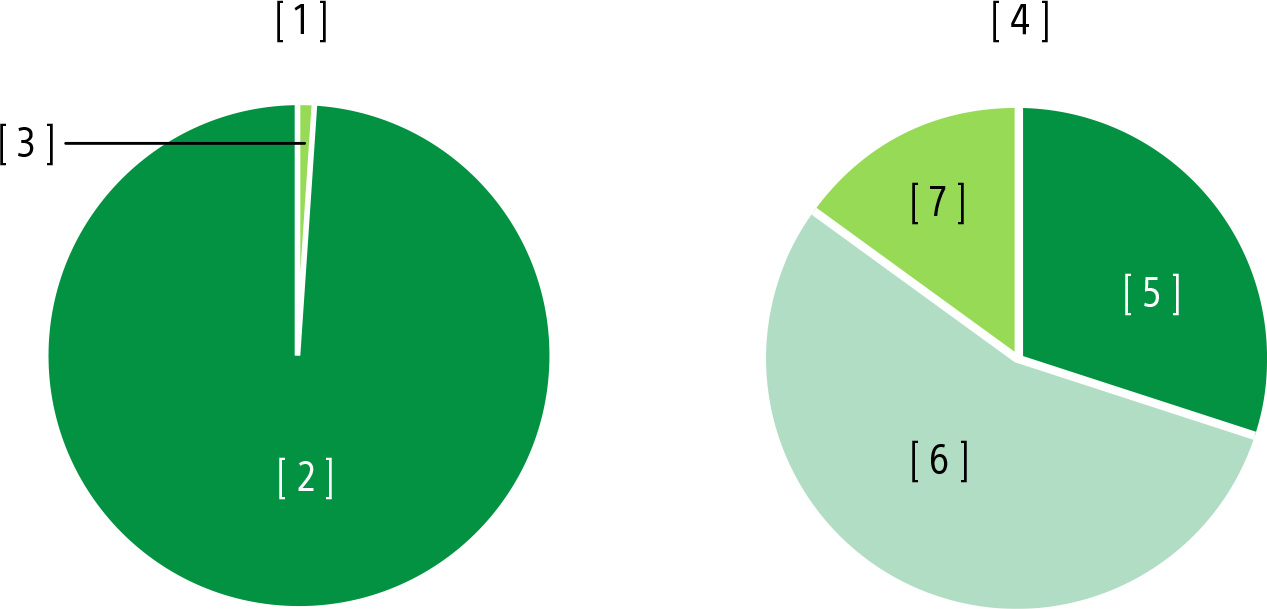

[1] SORPLAS

[2] Recycled content 99%2 [3] Flame retardants, other additives 1%

[4] Typical recycled polycarbonate plastic3

[5] Petroleum-based virgin plastic 55%4 [6] Recycled content 30% [7] Flame retardants, other additives 15%

Enhancing the ZV-1F with SORPLAS

We use SORPLAS0 in the ZV-1F in both its external and internal parts. This high-performance recycled plastic offers the dual benefits of improving the product while reducing its environmental impact.

SORPLAS across a wide variety of our cameras

We've used approximately 379 tons0 of SORPLAS recycled plastic in our digital cameras and digital video cameras over the past ten years.

Packing for a better future

Reducing plastic packaging

To eliminate our use of plastic in packaging, we’re now using plant-based non-woven fabric0 or paper bags, when the materials are available1, to wrap our products while maintaining the protective and high cushioning properties.

Reducing our carbon footprint at production plants

100% renewable energy for ZV-1F production

At Sony, we’re reducing energy use not only through our product design, but also in our manufacturing process. The production plants0 in Thailand1 and China2 that manufacture the ZV-1F now run on 100% renewable energy. We’re not stopping there: we’re accelerating our plan to introduce renewable energy at our sites across the world.